With the fast advancement of the aquaculture market, standard farming methods have been far from meeting individuals's demands. The demands for tank farming fish feed made by fish feed extruder device are not just balanced nutrition, excellent stability of the feed in water, no contamination to water high quality, and so on, and also more stringent requirements are put forward for the environmental high quality of fish survival.

The feed produced by the aquaculture fish feed extruder maker is tough pellets, and the other is the extruded feed pellet equipment, as well as the processed fish feed is soft pellets.

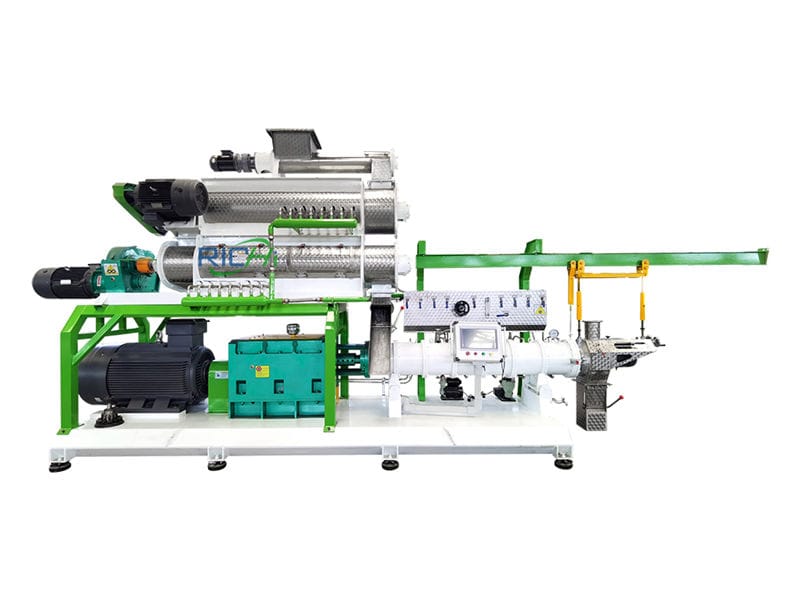

Today, Richi Machinery will discuss the extruded feed fish feed extruder maker. The manufacturing process normally takes on additional crushing and also second active ingredient mixing, and after that travels through extrusion, drying, external spraying, cooling down, crushing and also screening to complete the processing of water extruded feed.

Related post: fish feed plant

1. Resources cleaning and also primary grinding.

There are typically two kinds of resources utilized in drifting fish feed factories: one is powder, which does not need to be coarsely pulverized. For this kind of resources, it can straight go into the cone-shaped cleansing display to remove impurities after going through the feeding pit as well as elevator, and then carry out magnetic separation, and directly get in the batching container via the distributor or screw auger to participate in the initial batching;.

The material that requires to be coarsely shattered-- granular material. This sort of product enters the cleaning equipment through the discharging pit and also the elevator to enter the cleaning equipment for magnetic splitting up of pollutants, and afterwards gets in the to-be-pulverized container.

For specific resources, such as shrimp coverings, they can be directly taken into the silo to be squashed after magnetic splitting up without preliminary sieving.

One-time crude pulverization is the pretreatment procedure of ultrafine pulverization in water feed processing. Its major objective is to decrease the pellet size distinction and variant variety of products, enhance the functioning problem of the ultrafine pulverizer, and improve the working efficiency and also guarantee of the ultrafine pulverizer.

The product quality is stable; at the same time, in order to boost the working environment of employees and also reduce cross-contamination, it is advised to utilize an independent dust removal air internet, that is, an independent dust elimination system for the feeding port.

Related post: https://www.pellet-richi.com/fish-feed-extruder/aquatic-feed-pellet-production-line.html

2. The initial batching and also mixing.

The initial batching is generally the preparation of public basic materials, that is, the preparation of bigger materials in the formula. This fish feed extruder maker procedure is primarily finished by digital batching ranges.

Nonetheless, in the initial batching procedure, unique focus must be paid to the arching issue of the batching bin, which is mainly caused by the light bulk thickness and inadequate fluidness of the raw products of the water feed, specifically the high-grade marine feed basic materials. Therefore, particular anti-arching procedures must be considered the batching bin, such as using eccentric discharge, resonance motor, and so on.

The single-shaft horizontal bow mixer can be used for the first mixing, as well as the grease addition system need to be taken into consideration on the mixer. The initial batching and mixing is likewise the pre-treatment process of ultra-fine pulverization.

This auxiliary devices of fish feed extruder machine is mainly to minimize the variant series of material pellet dimension, boost the functioning condition of the pulverizer, boost the working performance of the pulverizer, as well as ensure the quality of the item.

Related post: fish feed machine

3. Secondary squashing and mixing of secondary active ingredients.

As a result of the low food consumption, short digestive system system and also inadequate digestive capacity of marine pets, water feed calls for really fine squashing pellet dimension to increase the surface area of the feed, enhance the contact location between the digestive system juice of aquatic animals and also the feed, and also improve the ability of water animals to feed the feed.

At the same time, as a result of the reduced intake of marine animals, the mixing harmony of the feed is needed to be mirrored in a smaller sized variety, which likewise requires the water feed to have a finer pellet size.

For instance, the shrimp feed must all pass through the 40-mesh analytical sieve, and also the content on the 60-mesh sieve ought to be less than 5%, so the micro-grinding process should be taken on.

In the additional pulverization procedure, the materials mixed in the very first time are raised by the lift and then get in the silo to be shattered, and then get in the micro pulverizer. Micro-pulverizers are generally made use of in the processing of water feeds, as well as vertical-axis micro-pulverizers are usually made use of, which are outfitted with powerful wind separation tools, and after that enter the rotary grading screen for testing.

The objective of configuring the rotary grading screen here is mainly to remove the fine fluff formed by the crude fibers in the feed during the pulverization procedure, since the existence of these fine fluff is very easy to follow the die hole of the fish feed extruder maker till the die hole is obstructed, triggering Shut down for cleaning, so it must be removed.

The cleaned up materials go through additional batching as well as blending. Because the excellence of the products going into the second batching blending container is above 60 mesh and the density is little, special focus must be paid to the sensation of arching.

In order to stop this sensation, on the one hand, the eccentric sub-expansion hopper can be used, as well as on the other hand, all the material discharge equipments that have actually undergone ultra-fine grinding use an impeller feeder, which not only has an arch breaking mechanism, but likewise can flexibly adjust the circulation price. size. Various basic materials enter the additional mixer after additional batching.

There is an artificial feeding port over the second mixer, which is mostly utilized for the addition of trace additives. At the same time, there is a liquid addition mechanism on the mixer for the addition of grease; one is for the enhancement of water. In the second mixing procedure, different materials have to be completely combined, as well as the coefficient of variant CV is less than 7%, which is the crucial to guaranteeing item top quality.

Therefore, the mixer must pick a model with superb efficiency, such as double-shaft straight paddle mixing It has high mixing harmony, high result and also rapid mixing speed. After secondary squashing and secondary component mixing, the material gets in the succeeding procedure-- expansion granulation procedure-- with fish feed extruder maker.

Related post:

4. Extrusion process by fish feed extruder device.

In the extrusion procedure, the material in fact undertakes a cooking process under the conditions of heat, high moisture and high pressure.

Throughout this fish feed extruder device procedure, the physical and also chemical residential properties of the material changed strongly, and currently when the product was squeezed out from the die hole, the water in the feed was immediately converted from fluid to aeriform state as well as released from the feed because the stress unexpectedly dropped from high pressure to concerning 100kPa.

Consequently, the product is extruded by fish feed extruder device to develop the supposed extruded feed. Because this kind of feed not just has the advantages of basic difficult pellet feed - good palatability, avoids automatic grading of items, is easy to move, aids food digestion, minimizes waste in the feeding procedure, etc, but likewise has unique advantages:.

In the feed, the starch has a high level of gelatinization by fish feed extruder machine, the protein is more absorbable, as well as the utilization rate of the pet feed is boosted; it has outstanding floatability, which is very easy to observe the feeding scenario of the fish, and can manage the water pollution to the optimum level. These are likewise the main reasons that extruded feed is widely used.

There are numerous sort of clothes dryers can be utilized after fish feed extruder device. When the diameter of the pellets is less than 4mm, a shaking fluidized bed clothes dryer can be selected; when the size of the pellets is greater than 4mm, a belt dryer can be chosen, or a straight float dryer can be directly chosen.

Since this type of dryer can make the material in a semi-suspended state on the whole screen surface, it can not only make sure the drying out impact, but additionally decrease the damages to the pellets. After the material is dried out, it enters the outside spraying system.

The exterior spraying of the pellets is mainly to meet the fish's energy demands and lower the loss of heat-sensitive materials throughout processing. The nutrients that need to not be added in the previous procedure can be supplemented by exterior spraying, as well as at the same time, the palatability of the feed can be improved as well as the powder content can be lowered.

The maximum functioning temperature for this procedure is around 80 ℃. After the product travels through the outside splashing system, it can enter the counter-flow cooler for air conditioning.

5. Ended up product packaging.

The cooled down product is lifted by the elevator and then squashed into the plane rotary display for classification. The grading filter utilized after fish feed extruder maker is typically a two-layer sieve, and the material on the lower screen is the completed product, which can be straight entered into the ended up item storehouse, and then considered as well as packaged. The product on the top sieve requires to be returned to the crusher for crushing. The product under the reduced screen is generally carefully crushed, which can be returned to the batching container as waste.

The fish feed extruder equipment production process analyzed above is the standard setup of the existing water extruded feed handling modern technology. Using this process, sinking feed, slow sinking feed as well as drifting feed can be generated.

Although extruded fish feed extruder equipment innovation has actually been recognized by several suppliers as a new sort of processing innovation, it has actually not been commonly made use of because its financial investment is a lot larger than that of tough pellet feed processing modern technology.

Nevertheless, the fish feed extruder equipment puffing procedure is the future advancement pattern of the feed processing sector, particularly in the application of marine pet feed and also family pet feed, and also will most definitely replace the standard difficult pellet feed handling technology.

I wish the above relevant material regarding fish feed extruder maker is practical to you. For more details regarding floating fish feed granulator device, you are welcome to consult the staff of Richi Equipment, we will serve you wholeheartedly!

For details please contact: feed machine

WhatsApp:86 138 3838 9622

Email:enquiry@pellet-richi.com