For a very long time, Richi Machinery insists on advertising the development of the market with the idea of serving consumers with technology, information and knowledge, and also has been recognized by consumers and praised by industry organizations. In order to far better offer the consumers of this job, guarantee the high quality of the total job, as well as guarantee the fast and also reliable shipment, Richi Equipment has actually established a special service group in the Russian language area. By the end of 2021, Richi Machinery has actually completed a variety of high-quality feed assembly line for Russia, Uzbekistan, Kazakhstan, Turkmenistan as well as other nations, and all of them have been sent to Russia as well as various other countries a few kilometers away. Early conclusion to lay the foundation.

Related post: Feed Mill Plant

1. Attributes of RICHI Feed Manufacturing Facility Project:

( 1) The entire assembly line is fully automated, and each section can be begun intelligently with one trick, which greatly reduces human errors as well as labor costs and enhances manufacturing performance.

( 2) The procedure of the whole plant can realize data management, as well as realize the information web link in the entire procedure from raw materials going into the factory to complete items leaving the manufacturing facility, so as to make sure the reliable and trustworthy procedure of the whole manufacturing monitoring.

( 3) The intelligent manufacturing management system provides a range of control approaches, as well as different recipe storage space and changing can fulfill the requirements of individualized personalization; rich record features, information monitoring of each storehouse, two-way traceability features, etc, can resolve the trouble of low food safety and security guarantee and also high quality. Untraceable and various other concerns.

Related post: https://www.pellet-richi.com/complete-feed-mill-for-sale

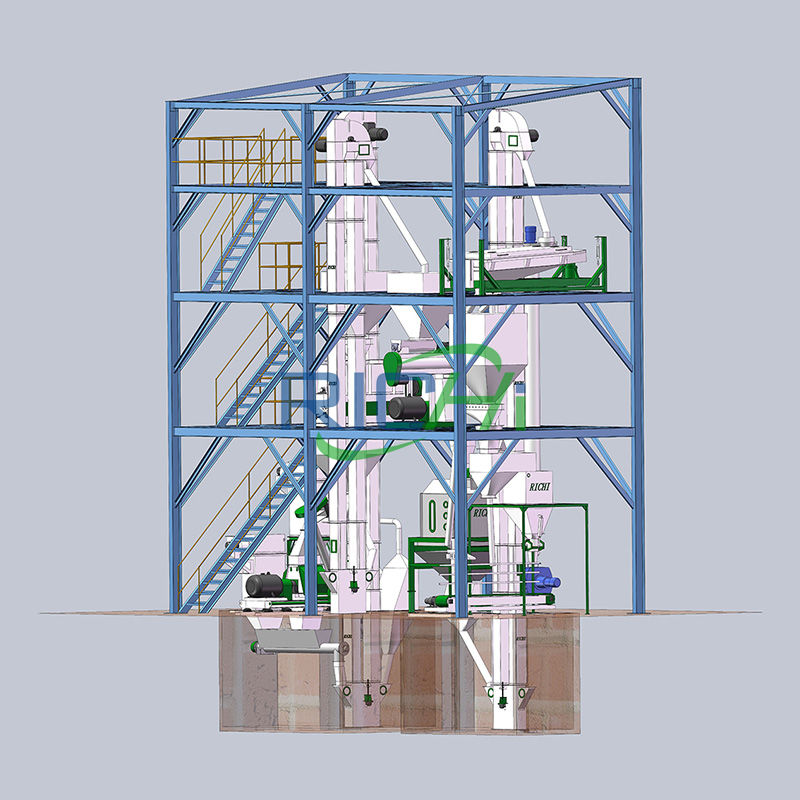

( 4) Three-dimensional electronic factory layout, specific planning, ingenious and also improved mechanical devices and feed process, risk-free and eco-friendly, can properly avoid cross-contamination and solve dirt issues.

Richi Machinery, focusing on engineering quality, has experience in designing tens of countless assembly line for more than 3,000 high-grade feed tasks around the world, from comprehensive plant preparation, format design, procedure style, tools customization, installation as well as appointing, electric system control, to production. A collection of web links such as modern technology and upkeep training are the very first in the market. The project entails livestock and chicken feed, aquatic feed, pet dog feed, premixed feed, focused feed, jump pellet manufacturing, compound plant food, warehousing engineering, timber pelleting and also garbage disposal, and so on, and also is devoted to developing a harvest assembly line for clients to survive.

2. Key feed mill tasks.

( 1 ) 10-15T/H Animal Feed Factory in Uzbekistan

Country : Uzbekistan.

Capability : 10-15T/ H.

Feed Dimension : Chicken mash feed as well as 2-6mm pellets.

MAIN POWER : 520KW.

Workshop dimension( L * W * H) : 35m * 20m * 25m.

( 2 ) 10-15T/H Poultry Feed Mill Plant in Uzbekistan

Nation : Uzbekistan.

Capacity : 10-15T/ H.

Feed Size : Poultry mash feed and 2-6mm hen pellets.

KEY POWER : 410KW.

Workshop size( L * W * H) : 12m * 12m * 25m.

( 3 ) Uzbekistan 10T/H Feed Plant For Chicken As Well As 5T/H Feed Plant For Premix Manufacturing.

Nation : Uzbekistan.

Capacity : 15T/H.

Feed Pellet Size : 2-6mm chicken pellets and premix powder.

The install duration : 60 Days.

Workshop size( L * W * H) : 12m * 12m * 25m.

Related post:22t/h animal feed factory

( 4 ) 5-6T/ H Fish Feed Plant for Premium Trout Pellets Drive right into Russia.

The trout food pellets manufacturing procedure of this personalized 5-6tph totally autonatic fish feed plant project takes on pulverization and then batching, periodic mixing, (ultra) great pulverization, second batching, squeezing out, drying, oil injection, cooling (air cooling), sieving right into the finished item warehouse and also product packaging.

For details please contact: Richi Machinery

WhatsApp : 86 138 3838 9622.

Email:enquiry@pellet-richi.com.