Efficiency, precision, and repeatability are essential requirements in automotive manufacturing. The integration of automation with traditional manufacturing processes has transformed the way automotive components are produced, particularly when it comes to plastic parts.

At the centre of this integration lies End of Arm Tooling (EOAT), the engineering solution that connects robotic automation with injection moulding machines to streamline production and ensure consistent quality.

Understanding End Of Arm Tooling

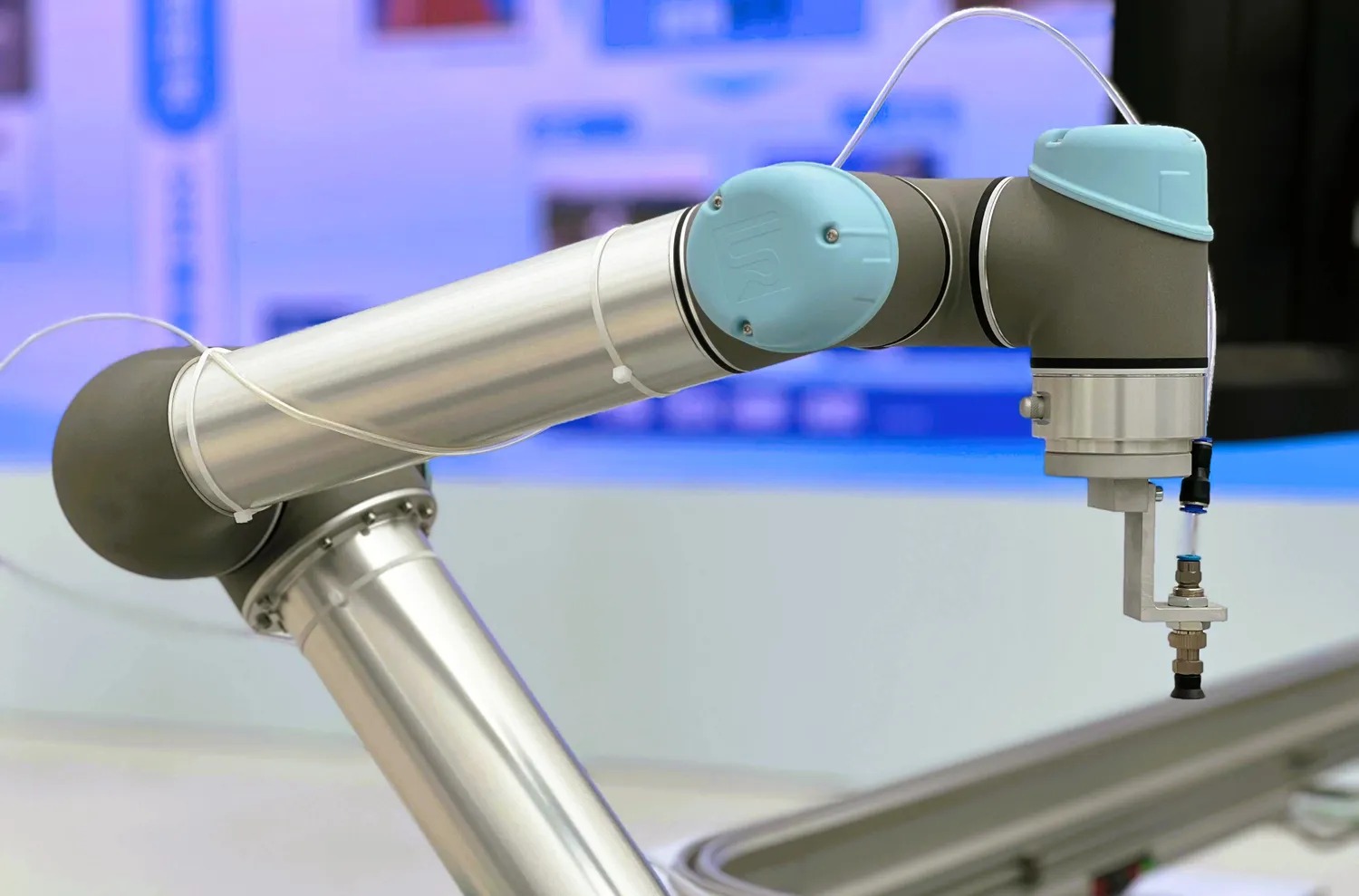

End of Arm Tooling refers to the devices attached to the end of robotic arms that interact directly with parts, materials, or machinery. In the context of injection-moulded automotive plastics, EOAT performs tasks such as picking finished components from the mould, transferring them along the production line, or placing them for assembly and inspection.

The design of EOAT is highly specialised. Each tool must match the geometry, weight, and handling requirements of the plastic component it manipulates. A well-engineered EOAT allows robots to perform repetitive tasks with high precision, reducing the risk of part damage and minimising production errors.

The Role Of EOAT In Injection Moulding

Injection moulding is a highly precise process where molten plastic is injected into moulds to form complex shapes. Once the part has cooled, it must be removed quickly and safely to maintain production efficiency. Traditionally, this required human operators, but manual handling introduces risks of inconsistency, damage, and slower throughput.

EOAT bridges this gap by allowing robots to handle the delicate process of part removal. Tools can be customised with features such as suction cups, grippers, or mechanical clamps that conform to the shape of the part. This ensures that even intricate or fragile components are safely extracted from the mould, ready for the next stage in the production process.

Enhancing Production Efficiency

One of the most significant advantages of EOAT is enhanced production efficiency. By automating the transfer of injection-moulded parts, manufacturers can maintain a continuous workflow without relying on manual labour. Robots equipped with EOAT operate consistently at high speeds, reducing cycle times and increasing overall throughput.

In addition, EOAT can be designed to handle multiple parts simultaneously, further optimising the production process. For automotive manufacturers, where large volumes of identical components are required, this level of efficiency is essential to meet demand while keeping costs under control.

Improving Quality And Consistency

Quality control is another area where EOAT adds value. Manual handling of injection-moulded parts can introduce variability, leading to defects or inconsistencies. By standardising the handling process with robotics, EOAT ensures that each component is treated identically, reducing the likelihood of scratches, warping, or other damage.

Furthermore, EOAT can be integrated with sensors and vision systems to inspect parts as they are handled. For example, a robotic arm can check for defects, measure dimensions, or verify that the correct part has been picked from the mould. This combination of automation and inspection improves quality assurance and reduces waste, which is particularly important in the automotive sector where safety and performance standards are critical.

Customisation And Flexibility

EOAT is highly versatile, which makes it an ideal solution for automotive manufacturers producing a wide range of plastic components. Each tool can be tailored to specific part geometries, weights, and handling requirements. This flexibility allows manufacturers to switch production lines between different models or components without significant downtime.

For example, a gripper designed for a car dashboard panel can be swapped or adjusted to handle smaller trim pieces or more complex parts. This adaptability ensures that automotive manufacturers can respond quickly to market demands, implement design changes, and maintain efficient production schedules.

Reducing Labour Costs And Workplace Risks

By automating the handling of injection-moulded parts, EOAT also reduces reliance on manual labour. This not only lowers labour costs but also improves workplace safety. Handling hot, heavy, or awkward plastic components can pose risks of injury to operators, and repetitive tasks can lead to musculoskeletal problems.

With EOAT, robots perform these tasks safely and consistently. Human operators can be redeployed to higher-value activities, such as process optimisation, quality control, or design improvement, enhancing overall productivity and job satisfaction.

The Future Of EOAT In Automotive Plastics

As automotive manufacturing continues to evolve, the role of EOAT is set to expand. Advances in robotics, artificial intelligence, and sensor technologies are enabling more sophisticated handling solutions. Future EOAT systems will be capable of not only moving parts but also performing assembly, sorting, and in-line quality checks, all within a fully automated workflow.

Sustainability is also a growing focus. EOAT can help reduce waste by minimising part damage during handling and optimising material use. By integrating automation and EOAT into production, manufacturers can achieve leaner, more efficient, and environmentally responsible operations.

EOAT As The Essential Link Between Moulding And Automation

End of Arm Tooling is more than just an accessory for robotic arms — it is the engineering bridge that links injection moulding with automation in automotive plastics manufacturing. By enhancing efficiency, consistency, flexibility, and safety, EOAT allows manufacturers to produce high-quality components at scale while maintaining control over costs and workflow.

For automotive companies seeking to stay competitive in a rapidly evolving industry, investing in advanced EOAT solutions is not merely an option — it is a necessity. It ensures that every plastic component moves seamlessly from mould to production line, setting the foundation for high-quality vehicles and efficient, future-ready manufacturing.