As industries move toward smarter, more efficient systems, both mechanical and thermal components play a pivotal role in powering modern technology. From machines that demand precise motion control to devices that require advanced temperature regulation, components like bevel gears and Peltier modules are fundamental in achieving reliable performance.

A bevel gear is a type of gear where the gear teeth are cut on a conical surface. These gears are designed to transmit power between two intersecting shafts, typically at a 90-degree angle. Bevel gears are commonly used in power tools, automotive differentials, industrial machinery, and marine equipment, where changing the direction of a drive is necessary.

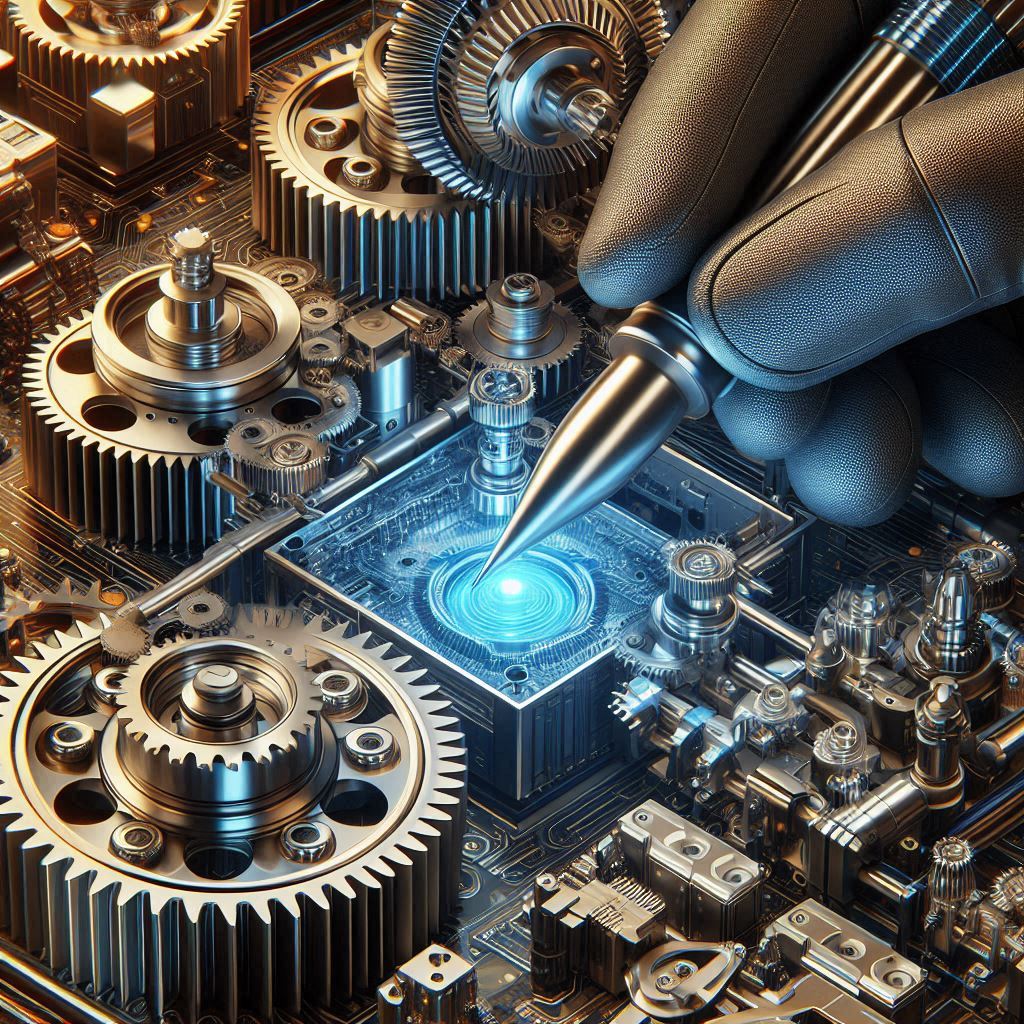

The major benefit of bevel gears lies in their ability to efficiently transfer motion and torque in compact spaces. They can be found in both high-speed and low-speed machinery, offering versatility in a wide range of applications. Depending on the design—straight, spiral, or hypoid—bevel gears can be optimized for either quiet operation or maximum torque. Their sturdy build and precise tooth engagement make them an ideal choice in equipment where durability and smooth motion are essential.

On the other side of technological advancement, temperature control has become a vital factor in both industrial and consumer electronics. A peltier module , also known as a thermoelectric cooler, is a solid-state active heat pump that transfers heat from one side of the device to the other when electrical current passes through it. It is widely used in portable refrigerators, computer CPU cooling systems, laser devices, and even scientific instruments.

The appeal of Peltier modules lies in their compact size, lack of moving parts, and ability to deliver precise temperature control. Unlike traditional cooling systems that rely on compressors or fans, Peltier modules offer silent operation and can maintain stable temperatures in confined spaces. While they are less efficient for large-scale cooling, they are perfect for applications where space, noise, and vibration must be minimized.

Combining mechanical reliability with thermal innovation, bevel gears and Peltier modules represent two crucial elements in the design of modern systems. Imagine a high-tech manufacturing machine where bevel gears drive mechanical components with precision while Peltier modules manage heat-sensitive elements to prevent overheating.