Air compressors play a pivotal role in the construction industry, providing a versatile source of power for various tools and equipment. Understanding the dynamics of air compressor construction is crucial for optimizing efficiency and safety on construction sites.

What is an air compressor?

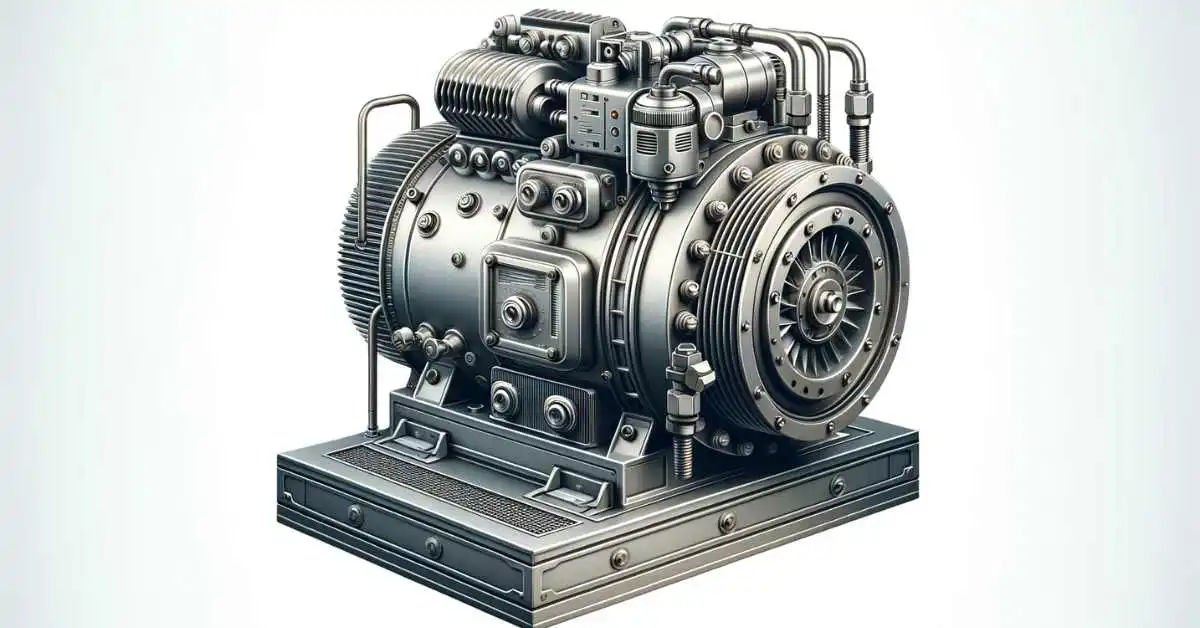

At its core, an air compressor is a mechanical device that converts power into potential energy stored in compressed air. This compressed air is then utilized to power pneumatic tools and equipment commonly used in construction. Importance in construction

The significance of air compressors in construction cannot be overstated. They power a wide array of pneumatic tools, including impact wrenches, drills, nail guns, and staplers, enhancing the speed and precision of various tasks.

Types of compressors

There are several types of air compressors, each suitable for specific applications. Understanding these types is essential for selecting the right compressor for construction projects.

How Air Compressors Work

Basic functioning

Air compressors operate on a simple principle: they use a motor or engine to generate compressed air by squeezing it into a storage tank. This stored air is then released in controlled bursts to power tools.

Components and their roles

Key components such as the compressor pump, motor or engine, storage tank, and pressure regulator work collaboratively. The pump pressurizes the air, the motor powers the pump, and the regulator ensures the controlled release of compressed air.

Types of Air Compressors in Construction

Reciprocating compressors

Reciprocating compressors use a piston-cylinder mechanism to compress air. They are suitable for intermittent use and are commonly found on construction sites.

Rotary screw compressors

Ideal for continuous use, rotary screw compressors operate through two interlocking helical rotors. Their efficiency and reliability make them popular in construction settings.

Centrifugal compressors

Centrifugal compressors rely on a high-speed rotating impeller to generate compressed air. While less common in construction, they find application in large-scale projects.

Pneumatic Tools in Construction

Impact wrenches and drills

Air compressors power impact wrenches and drills, providing construction workers with high torque and fast drilling capabilities.

Nail guns and staplers

Nail guns and staplers driven by compressed air streamline tasks like framing and roofing, significantly improving efficiency and precision.

Portable Compressors for Construction Sites

Advantages and applications

Portable air compressors offer flexibility on construction sites, enabling mobility and adaptability. They are indispensable for tasks in remote locations or areas with limited power sources.

Considerations when choosing

When selecting a portable compressor, factors such as size, power, and air delivery capacity must be considered to match the specific needs of the construction project.

Maintenance Tips for Air Compressors

Regular checks and inspections

Routine inspections ensure that components are in good working condition, reducing the risk of unexpected breakdowns and extending the lifespan of the compressor.

Cleaning and lubrication

Keeping the compressor clean and well-lubricated enhances its efficiency and prevents the accumulation of dirt or debris that could compromise performance.

Integrating Compressed Air Systems in Construction

Benefits for construction projects

Compressed air systems offer benefits such as consistent power delivery, versatility, and the ability to operate multiple tools simultaneously, improving overall project efficiency.

Ensuring efficiency and safety

Proper installation and maintenance of compressed air systems are crucial to ensuring both efficiency and safety on construction sites. Regular checks prevent leaks and guarantee optimal performance.

Safety Measures in Using Air Compressors

Proper training and guidelines

Construction workers should undergo proper training on the safe use of air compressors, including understanding potential risks and emergency procedures.

Personal protective equipment (PPE)

Wearing appropriate PPE, such as safety glasses and hearing protection, is essential when working with air compressors to minimize the risk of injuries.

Challenges in Air Compressor Usage in Construction

Temperature and humidity considerations

Extreme temperatures and humidity levels can impact the performance of air compressors. Adequate measures should be taken to address these challenges and ensure consistent functionality.

Noise pollution and mitigation

The noise generated by air compressors can contribute to on-site noise pollution. Implementing soundproofing measures or using quieter compressors helps mitigate this issue.

Future Trends in Air Compressor Technology

Automation and smart features

The integration of automation and smart technologies in air compressors is an emerging trend, offering improved control, monitoring, and energy efficiency.

Eco-friendly innovations

The construction industry is increasingly adopting eco-friendly air compressors that minimize environmental impact through reduced emissions and energy consumption.

Conclusion

Understanding the nuances of air compressor construction is vital for anyone involved in the construction industry. From selecting the right type of compressor to ensuring proper maintenance and safety measures, this knowledge enhances efficiency, productivity, and overall project success.

FAQs

Q1: Can air compressors be used for tasks other than construction?

Yes, air compressors have versatile applications beyond construction, including manufacturing, automotive, and home improvement projects.

Q2: Are portable air compressors as powerful as stationary ones?

Portable compressors vary in power, but some models can deliver comparable performance to stationary compressors for specific tasks.

Q3: How often should air compressors undergo maintenance?

Regular maintenance checks are recommended, with the frequency depending on factors such as usage, environmental conditions, and the type of compressor.

Q4: Are there safety risks associated with using air compressors?

Yes, improper use of air compressors can pose safety risks. It's crucial to follow safety guidelines, wear appropriate PPE, and undergo proper training.

Q5: Can air compressors contribute to energy savings on construction sites?

Yes, efficient air compressor systems can contribute to energy savings by providing consistent power for tools, reducing the need for alternative power sources.