What is the welding point device and how does it work?

A look at the very distant past and according to the analysis of the tools discovered from the early centuries shows the fact that early man used the physical principles that today form the main basis of modern welding, that is, connecting metals to each other from By putting the hot and melted edges together and hitting the hammer, they tried.

In fact, one of the old methods of connections is the welding industry, which has been done since the past and is important. From the late 1930s, when the construction of bridges, railways, streets, and ocean-going ships, etc. began with the method of welding parts to each other, until today, when man is busy building spaceships, skyscrapers, nuclear power plants, and so on. microprocessors, etc., welding is still one of the most important methods of connection.

Today, we have reached a point where this technology is significantly out of a craft and is advanced towards full automation, for example, the use of robots (Robbates) that are guided by microprocessors to control and operate welding.

In addition to the development of welding methods, special attention has been paid to higher productivity, better economy, ease of work, and greater reliability of these methods.

Despite the development of welding methods in the industry, it is divided into two main groups, fusion welding and non-fusion welding, one of the sub-groups of non-fusion welding is resistance welding, which itself is divided into four methods. will be

1- Boiling point

2- Prominent weld

3- Welding

4- Head to head

Introduction to spot welding process

It is a technique in which the parts are welded together at the welding points, the welding zone is the surface on which the electrode is located and through which the current passes and is under pressure

The electrical contact resistance of the metal involved between the electrodes is the sum of the following resistances:

1- The contact resistance of the electrodes with the workpiece

2- Contact resistance between two workpieces

3- Electrical resistance of the workpiece

Experience has shown that the electrical contact resistance between the electrode and the workpiece is half of the electrical contact resistance of the two workpieces.

When the welding current is established, first the microscopic highlights of the surfaces of the two workpieces are heated due to the concentration of the current, and then the material adjacent to these welding point electrodes is made of copper alloys that have high thermal conductivity.

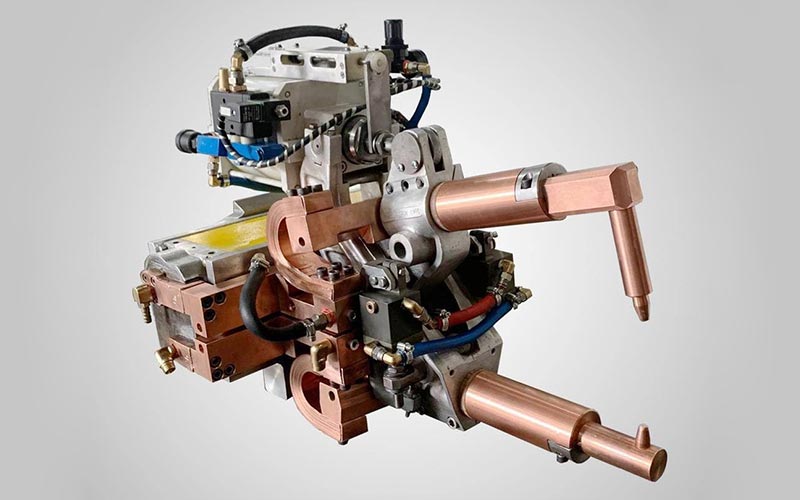

Specifications of the welding point device

The دستگاه نقطه جوش has two main designs: fixed (stationary) and mobile (portable), which has the following specifications:

1- The presence of a step-down transformer to create the high current required for welding

2- Control panel for precise control of flow time and required current intensity

3- The metal body of the device is suitable for its stationary or mobile application

4- It has tools made of non-ferrous metals to transfer current and pressure from the transformer to the work piece (jaws and arms).

5- With pneumatic or hydraulic cylinder or servomotor to create the pressure required for welding

6- The necessity of circulating water circuits in all parts of the machine to maintain working efficiency

source : electrotechnotak